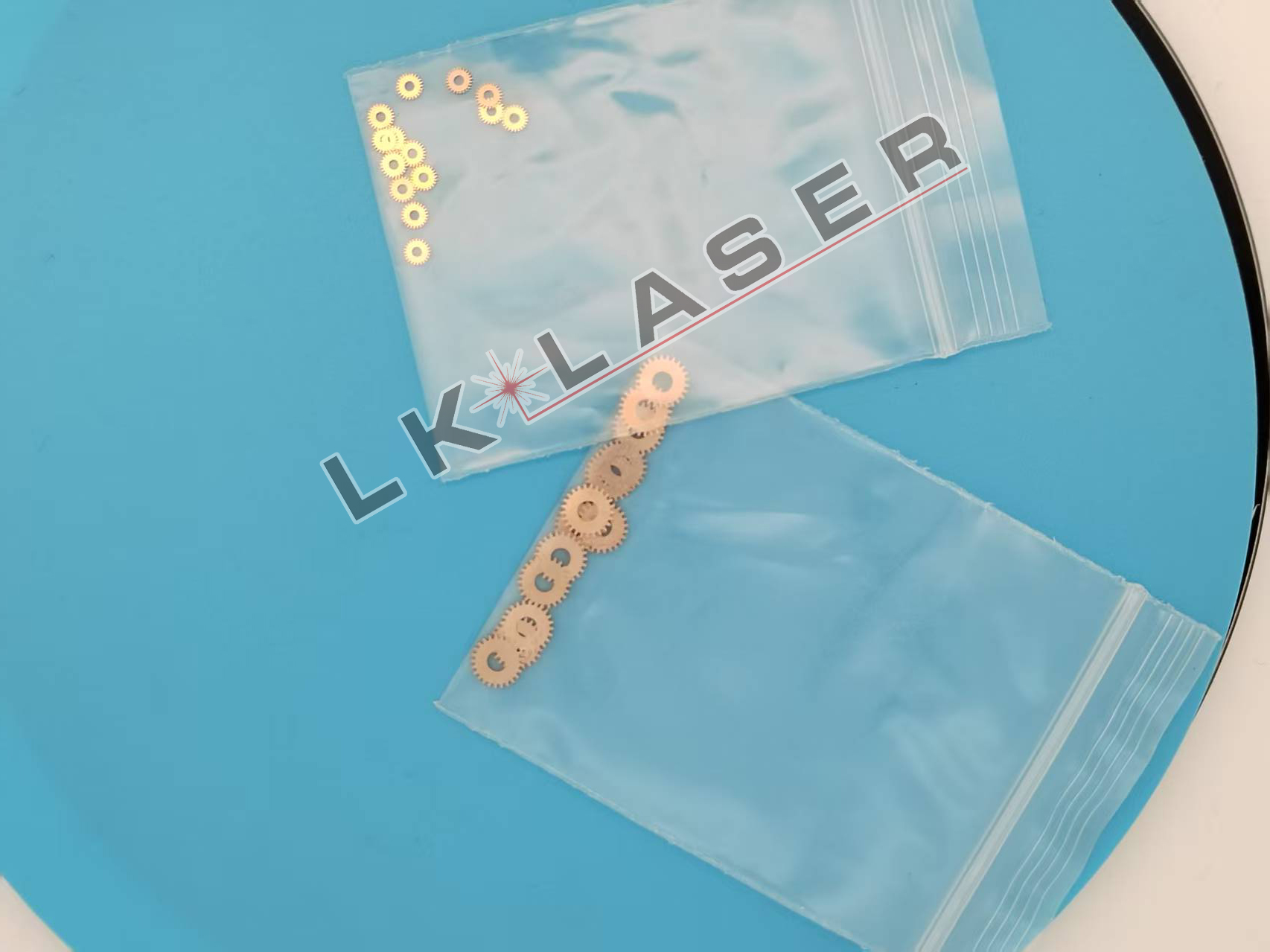

Laser cutting watch gear wheel tooth profile accuracy reaches ±1–5μm, with narrow kerf (20–30μm), capable of producing complex multi-tooth/irregular-shaped teeth.

Supporting materials: Brass alloy, Zinc-cooper alloy, Stainless steel, Rustproof steel, High speed steel, Gold alloy, Platinum alloy, Titanium alloy

Thickness range: 0.1~1mm

We can provide free laser cutting service!

24 Month maintenance

Fast delivery

24 Hour treatment

| Center Wheel | Carries the second hand and serves as the core gear for transmitting power from the barrel. |

| Third Wheel | Connects the center wheel and the fourth wheel to transfer power and adjust rotational speed. |

| Fourth Wheel | Directly drives the second hand and ensures basic timing accuracy. |

| Escape Wheel | Cooperates with the pallet fork to control the running frequency of the movement. |

| Barrel Arbor Gear | Fixed inside the barrel to output power for the movement. |

| Clutch Wheel | Exclusive to chronograph movements; controls the start, stop and reset of timing functions. |

| Setting Wheel | A component of the setting mechanism that drives the hour/minute wheel or date wheel to adjust time and date |

| Ratchet Wheel | Cooperates with the pawl to prevent reverse rotation of the mainspring and assist manual winding. |

| Lamellar Gear | Features an ultra-thin and flat structure, suitable for power transmission in ultra-thin watch movements. |

| Worm Gear | Cooperates with the worm wheel to reduce speed and increase torque, applied in date and moon phase display modules. |

|