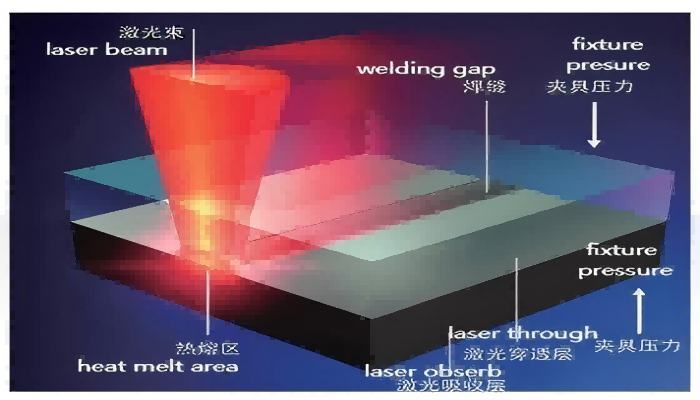

Laser welding technology uses the heat generated by a laser beam to melt the plastic contact surfaces, thereby bonding thermoplastic sheets, films, or molded parts together.

Cutting-edge Medical Laser Equipment: Reshaping the Future of Precision Manufacturing for Medical Instruments

Our booth No: 20.2G48 Company Name : Shenzhen Lei Kang Machinery Equipment Co.,Ltd Date: September 26-29 2025 Location: Canton Fair Convention Center

UV laser marking ceramics achieves higher quality marking effects and becomes the mainstream choice in ceramic blackening technology.

medical instrument permanent, non-fading, corrosion-resistant black UDI code serial number marking

Mopa laser ability to adjust pulse width and other parameters makes them ideal for applications that require minimal thermal damage, high-quality marking, and versatile material compatibility.

laser marking machine for paint stripping and coating removal

laser machine which used in optical eyewear industry